Rifling

Most

modern pistols, revolvers, rifles, and some shotgun barrels have what

are called rifling in their barrels.

Rifling consists

of grooves cut or formed in a spiral nature, lengthwise down the barrel of a firearm.

Rifling

is placed in the barrels of firearms to impart a spin on the

bullets that pass through it. Because bullets are

oblong objects, they must spin in their flight, like a

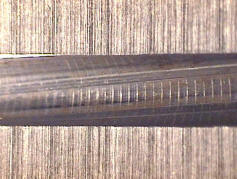

thrown football, to be accurate. Looking down the barrel of

a firearm you might see rifling like that depicted on the

right. This image shows a pattern of rifling

containing six

grooves with a right twist. Rifling

is placed in the barrels of firearms to impart a spin on the

bullets that pass through it. Because bullets are

oblong objects, they must spin in their flight, like a

thrown football, to be accurate. Looking down the barrel of

a firearm you might see rifling like that depicted on the

right. This image shows a pattern of rifling

containing six

grooves with a right twist.

In firearm examiner lingo we refer to the rifling as lands

& grooves. The lands are the raised areas between two grooves. A rifling pattern of eight grooves with

also have eight lands. Registered users only! See

new 3-D bullet.

Firearms

can be manufactured with any number of lands and grooves in their

barrels. They can also spiral either left or right. A few

of the more common

rifling patterns are 4/right, 5/right, 6/right, 6/left, 8/right,

and 16/right.

To see several rifling pattern illustrations

go to Registered users only! Rifling Illustrations Page.

The

procedures described below are abbreviated somewhat but I hope that

they will provide you a better understanding of basic rifling techniques.

When

barrels are manufactured, they start out as a solid rod of steel.

A hole is drilled down the center of the rod and the rifling is then

placed in the barrel.

There

are three basic machining processes that modern firearms manufacturers use

to form the rifling in barrels. Rifling can be cut into the

inner surface of a barrel using a broach, the rifling

can be formed using a hardened steel button, or the

rifling will be formed through a process called hammer forging.

A newer method of rifling barrels, called

Electrochemical Rifling, does not involve the normal

machining processes of the other techniques.

Broach Rifling

The

modern broach method of rifling uses a hardened steel rod with several

cutting rings spaced down the rod. Like the one shown below.

Broaches can be over 16 inches long and because they have several

cutting rings, they are referred to as gang broaches.

Each

successive cutting ring is slightly larger in diameter and when the last ring on the broach passes down the barrel the desired depth to the grooves

is obtained. The cutting rings have gaps evenly spaced around

them to allow for the lands. The rod is twisted as it is pulled

through the barrel and this forms the spiral to the rifling

pattern. A cut-away of the inside of a barrel below shows the

cut grooves and the lands with original drilling marks.

Button Rifling

Probably

the most common method used today to rifle barrels is button

rifling. Button rifling uses a different approach to forming the grooves in the

barrel. A button as seen below is a very hard steel plug that is

forced down an unrifled barrel.

The

grooves are then formed in the barrel under very high pressure.

The pressure created to form the rifling in the barrel hardens and

polishes the inside of the barrel.

Hammer Forged Rifling

The

newest mechanical method of rifling barrels is accomplished through a process called

hammer forging. Hammer forging produces a type of rifling called polygonal rifling. A hardened steel mandrel is

produced with the shape of the rifling formed on its outer

surface. The mandrel is inserted into a barrel blank and the

outer surface of the barrel is machine hammered. The hammering

forces the barrel material down against the mandrel and the inner

surface of the barrel takes on the shape of the mandrel. The

mandrel is then removed from the barrel and the outer surface of the

barrel is cleaned up. Just as in the other types of rifling,

polygonal rifling can have different patterns.

The most common polygonal patterns are 6/right and 8/right. This

form of rifling is used by Glock, Steyr, IMI, and a few other

manufacturers.

Electrochemical Rifling

In a process that eliminates the

conventional machining of metal, rifling is formed by wet-etching the

interior of a barrel under an electric current. The metal inside the

barrel is actually eaten away or dissolved to create grooves in the barrel.

An electrode (cathode) that has metal strips in the shape of the rifling is

placed in the barrel (anode) and the the assembly is submerged in a salt

solution. An electric current is applied and the electrode is moved

down the length of the barrel and twisted to create the spiral shaped

grooves. As the current travels from the barrel to the electrode metal

is removed by electrolysis thus forming the grooves in the barrel.

This process creates the rifling in the barrel very quickly and does not

require consumable tooling.

Both broach and button rifling are considered

conventional rifling techniques. The transition from a land to a groove is

very distinct and the lands and grooves are flat to slightly curved. The

two illustrations below show the rifling in two conventionally rifled

barrels.

|

|

|

|

Click for larger views

Registered users only! |

A bullet fired from a

conventional 6/right rifled barrel will have

impressions on it like those seen in the image below.

Because there is a distinct

edge at the transition from a land to a groove impression,

the widths of the lands and grooves can be measured.

Polygonal rifling on the

other hand is very different from conventional rifling.

There are no distinct transitions between the lands and the

grooves. The illustration below shows the polygonal rifling in a Glock 9mm LUGER pistol.

Click for larger view

Registered users only!

Polygonal

rifling takes on a shape that is sometimes referred to as "hills

and valleys." This gradual transition prevents firearm examiners

from measuring the individual rifling elements in a polygonal rifled

barrel. Provided a bullet is in good condition, polygonal

rifling impressions like those seen on the 40 caliber bullet below,

are fairly easy to spot.

Electrochemical rifling is

more similar in shape to the button and broach rifled

barrels but has slightly less distinct transitions between

the lands and grooves.

How do

these different rifling techniques effect firearms

identification? Click the Next button below to find out.

|